Estas cookies garantizan funcionalidades básicas y características de seguridad del sitio web, de forma anónima. Las cookies necesarias son absolutamente esenciales para que el sitio web funcione correctamente. The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies.

The cookie is used to store the user consent for the cookies in the category "Performance". This cookie is set by GDPR Cookie Consent plugin.

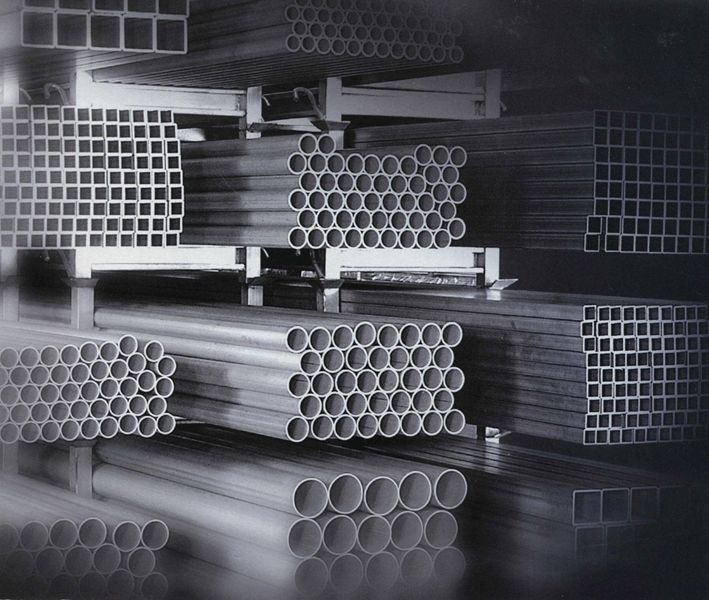

The cookie is used to store the user consent for the cookies in the category "Other. The cookies is used to store the user consent for the cookies in the category "Necessary". The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". The cookie is used to store the user consent for the cookies in the category "Analytics". These cookies ensure basic functionalities and security features of the website, anonymously. A seamless tube eliminates any such issues and thus offers high corrosion resistance.Necessary cookies are absolutely essential for the website to function properly.

0 kommentar(er)

0 kommentar(er)